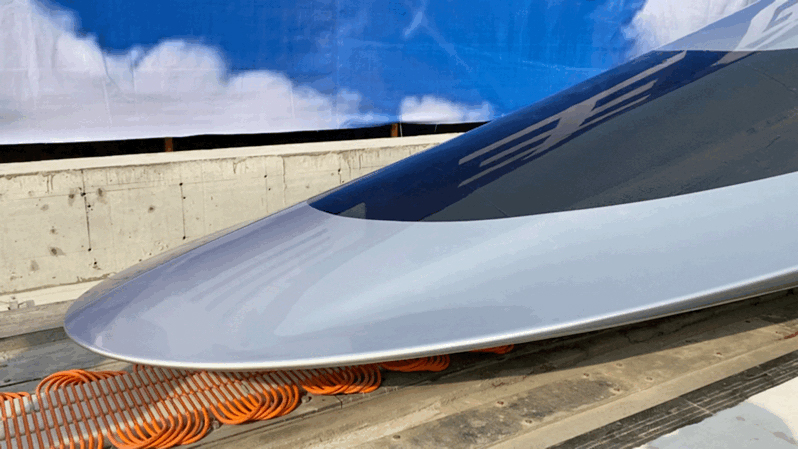

On the morning of January 13, 2021, the world's first high-temperature superconducting high-speed maglev engineering prototype and test line using the original technology of Southwest Jiaotong University was officially launched in Chengdu, Sichuan Province, China. It marks a breakthrough from scratch in the research of high temperature superconducting high speed maglev project in China and our country has the conditions for engineering experiments and demonstrations.

First Case In The World;Create A Precedent

The commissioning of the high-temperature superconducting magnetic levitation technology test line is the first in the world. It is a representative of China's intelligent manufacturing and created a precedent in the field of high-temperature superconductivity.

The high-temperature superconducting maglev train technology has the advantages of no source stability, simple structure, energy saving, no chemical and noise pollution, safety and comfort, and low operating cost.It is an ideal new type of rail transportation, suitable for a variety of speed domains, especially suitable for the operation of high-speed and ultra-high-speed lines; This technology is a high-temperature superconducting maglev train technology with self-suspension, self-guided, and self-stabilizing characteristics. It is a new standard rail transportation method facing future development and broad application prospects.The technology is first to be engineered in an atmospheric environment, and the expected operating speed target value is greater than 600 km/h, which is expected to create a new record for land traffic speed in an atmospheric environment.

The next step is to combine future vacuum pipeline technology to develop a comprehensive transportation system that fills the gaps in land transportation and air transportation speeds, which will lay the foundation for a long-term breakthrough in speeds above 1000 km/h, thereby building a new model of land transportation. Forward-looking and disruptive changes in the development of rail transit.

△ Future Renderings △

Magnetic Levitation Technology

At present, there are three "super magnetic levitation" technologies in the world.

Electromagnetic levitation technology in Germany:

The electromagnetic principle is used to realize the levitation between the train and the track. At present, the Shanghai maglev train, the maglev train under construction in Changsha and Beijing are all in this train.

Japan's low-temperature superconducting magnetic levitation technology:

Use the superconducting properties of certain materials at low temperatures (cooled to -269°C with liquid helium) to make the train levitate, such as the Shinkansen maglev line in Japan.

China's high-temperature superconducting magnetic levitation technology:

The principle is basically the same as that of low-temperature superconductivity, but its working temperature is -196°C.

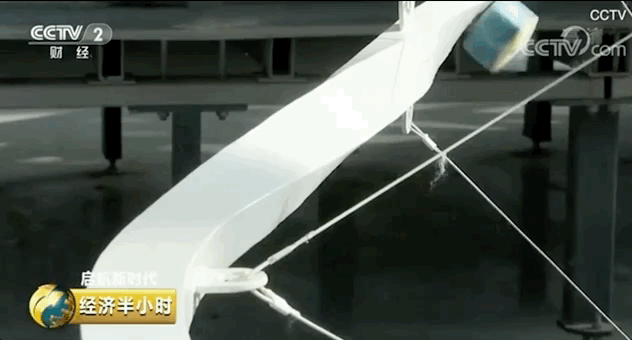

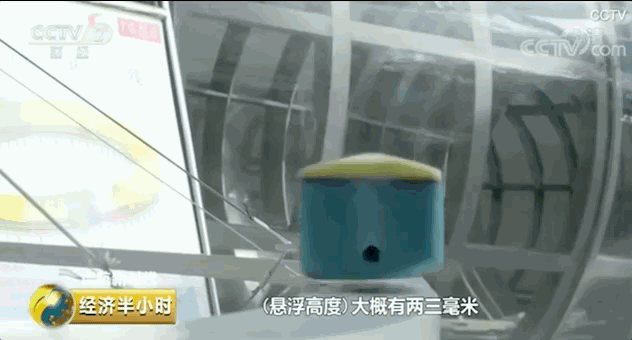

In previous experiments, this magnetic levitation in our country can not only be suspended but also suspended.

△ Liquid nitrogen and superconductors △

Advantages of High Temperature Superconducting Maglev Train

Energy saving: Levitation and guidance do not require active control or vehicle power supply, and the system is relatively simple. Suspension and guidance only need to be cooled with cheap liquid nitrogen (77 K), and 78% of the air is nitrogen.

Environmental protection: The high-temperature superconducting magnetic levitation can be levitation statically, completely without noise; the permanent magnet track generates a static magnetic field, and the magnetic field in the place where passengers touch is zero, and there is no electromagnetic pollution.

High speed: The levitation height (10~30 mm) can be designed as required, and it can be used to run from static to low, medium, high speed and ultra-high speed. Compared with other magnetic levitation technologies, it is more suitable for vacuum pipeline transportation (more than 1000 km/h).

Safety: The levitation force increases exponentially with the decrease of the levitation height, and the operation safety can be ensured without control in the vertical direction. The self-stabilizing guidance system can also ensure safe operation in the horizontal direction.

Comfort: The special "pinning force" of the high-temperature superconductor keeps the car body stable up and down, which is a stability that is difficult for any vehicle to achieve. What passengers experience when riding is "the feeling of no feeling".

Low operating cost: Compared with German constant-conductivity magnetic levitation vehicles and Japanese low-temperature superconducting magnetic levitation vehicles using liquid helium, it has the advantages of light weight, simple structure, and low manufacturing and operating costs.

Scientific and Technological Application of Liquid Nitrogen

Due to the characteristics of superconductors, the superconductor needs to be immersed in a liquid nitrogen environment at -196℃ during work.

High-temperature superconducting magnetic levitation is a technology that uses the magnetic flux pinning characteristics of high-temperature superconducting bulk materials to achieve stable levitation without active control.

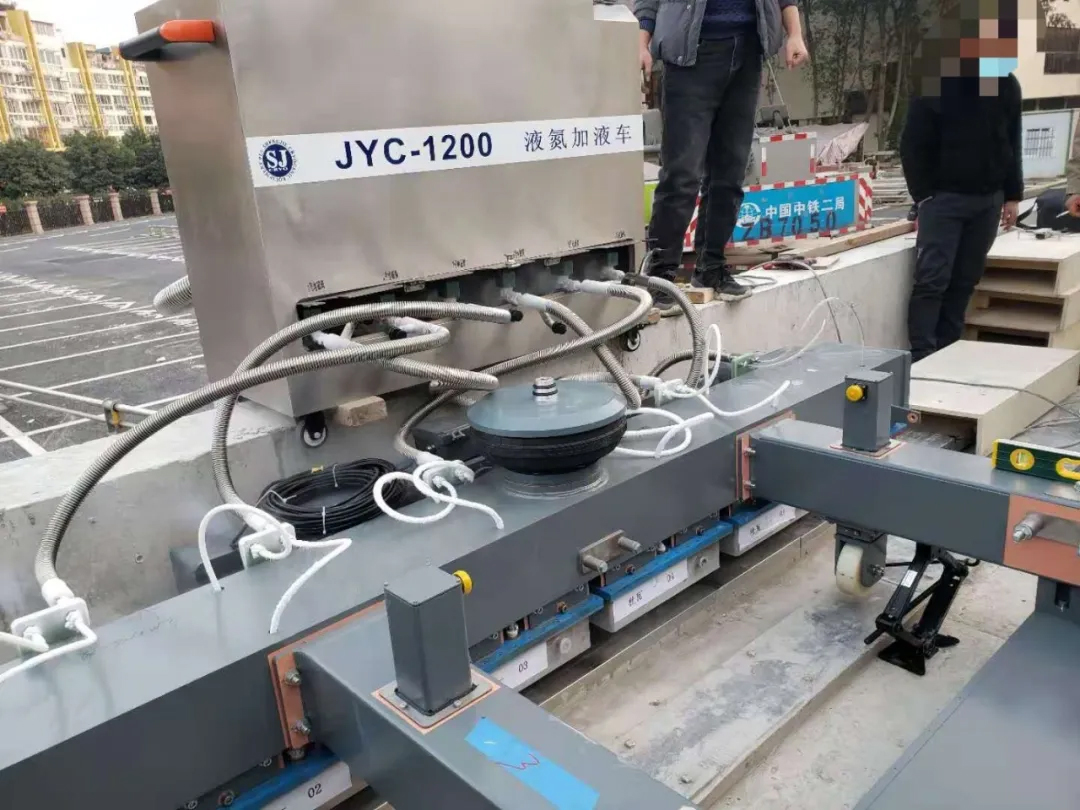

The Liquid Nitrogen Filling Truck

The liquid nitrogen filling truck is a product designed and developed by Sichuan Haishengjie Cryogenic Technology Co., Ltd. for the high-temperature superconducting high-speed maglev project.It is the core of maglev technology-Dewar supplement liquid nitrogen.

△ Field Application of Liquid Nitrogen Filling Truck △

Mobile design, liquid nitrogen replenishment work can be realized directly beside the train.

The semi-automatic liquid nitrogen filling system can supply 6 dewars with liquid nitrogen at the same time.

Six-way independent control system, each refill port can be controlled individually.

Low pressure protection, protect the inside of the Dewar during the refilling process.

24V safety voltage protection.

Self-Pressurized Supply Tank

It is a self-pressurized supply tank specially developed and manufactured for liquid nitrogen reserve. It has always been based on the safe design structure, excellent manufacturing quality and long storage days of liquid nitrogen.

△ Liquid Nitrogen Supplement Series △

△ Field application of self-pressurized supply tank △

Project in progress

A few days ago, we have worked with experts from Southwest Jiaotong University

Carried out the follow-up research work of the high-temperature superconducting high-speed maglev project

△ Seminar Site △

We are deeply honored to be able to participate in this pioneering work this time. In the future, we will also continue to cooperate with the follow-up research work of the project to make every possible step forward for this pioneering work.

We believe

China's science and technology will surely succeed

China’s future is full of expectations

Post time: Sep-13-2021